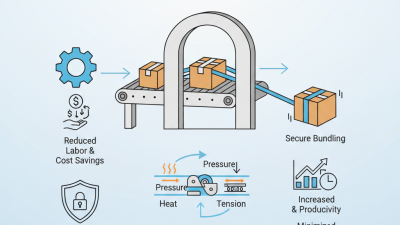

As industries evolve and automation continues to shape the manufacturing landscape, the automatic strapping machine has emerged as a pivotal tool in streamlining packaging processes. In 2025, we anticipate significant advancements in this essential equipment, driven by innovation and the need for greater efficiency. The automatic strapping machine not only minimizes the time consumed in packaging but also enhances the overall accuracy and security of the strapping process, making it an invaluable asset for businesses looking to optimize their operations.

With a focus on the latest trends, features, and benefits, this outline will explore how automatic strapping machines are adapting to meet the demands of various sectors. From increased automation capabilities to enhanced user interfaces, these machines are designed to boost productivity while reducing labor costs. Understanding these trends will provide valuable insights for companies seeking to upgrade their packaging lines and improve their competitive edge in the market. As we delve into the developments of automatic strapping machines, it is clear that their role will only become more critical in ensuring reliable and efficient packaging solutions in the years to come.

As we look forward to the trends in automatic strapping machines for 2025, several key features stand out that enhance efficiency and user experience. One of the most notable advancements is the integration of smart technology. These machines are becoming increasingly equipped with IoT capabilities, enabling real-time monitoring and data analytics. Users can track performance metrics and maintenance schedules, ensuring optimal operation and reducing downtime. This connectivity not only streamlines the packaging process but also improves overall productivity and management.

Another significant feature is the shift towards user-friendly interfaces and automation. Modern automatic strapping machines are now designed with intuitive controls, allowing operators to easily adjust settings and configurations. Advanced automation reduces the need for manual intervention, minimizing human error and increasing consistency in packaging. Additionally, adjustable strapping speeds and tension settings cater to various packaging needs, making these machines versatile across multiple industries. Overall, the convergence of smart technology and user-centric design makes the 2025 automatic strapping machines more efficient and adaptable than ever before.

The automatic strapping machine industry is poised for transformative growth in 2025, driven by advancements in technology and increasing demand for efficiency in packaging processes. According to a recent market analysis, the global automatic strapping machine market is projected to reach $1.1 billion by 2025, with a compound annual growth rate (CAGR) of 5.4%. This growth is primarily fueled by the rising need for cost-effective packaging solutions across various sectors including e-commerce, logistics, and manufacturing.

Emerging trends in automatic strapping technology highlight the integration of smart features that enhance machine performance and usability. One notable trend is the incorporation of Internet of Things (IoT) capabilities, which allow for real-time monitoring and predictive maintenance. Data from industry experts indicate that machines equipped with IoT functionalities can reduce downtime by up to 30%, significantly improving operational efficiency. Additionally, newer models are increasingly using advanced materials and eco-friendly options, aligning with sustainability goals and offering benefits like reduced waste and lower energy consumption. These innovations are set to redefine packaging standards, making automatic strapping machines more versatile and efficient than ever before.

Utilizing advanced automatic strapping machines presents significant benefits that enhance operational efficiency and reduce costs in various industries. According to a recent report by the Packaging Machinery Manufacturers Institute (PMMI), automated systems can increase packaging speed by up to 30% compared to manual processes. This increased speed allows businesses to throughput products faster, meeting rising consumer demand without compromising on quality. Additionally, the precision of automatic strapping reduces material waste by ensuring optimal use of strapping materials, which can lower overall packaging costs by an estimated 10-15%.

Moreover, the integration of advanced technologies such as smart sensors and IoT functionalities in automatic strapping machines enables real-time monitoring and maintenance alerts. This capability not only reduces the likelihood of machine downtime but also extends the lifespan of equipment. A study by Freedonia Group indicates that companies utilizing automated packaging solutions experience a decrease in labor costs of around 20%, as fewer employees are needed to oversee and operate machinery. As businesses increasingly prioritize efficiency and sustainability, the benefits of adopting automatic strapping technology become increasingly clear, positioning them competitively within the market.

When selecting an automatic strapping machine, several important considerations must be taken into account to ensure optimal performance and efficiency. First, the machine's throughput is crucial - it should match the production speed of the operation. According to a recent industry report by Research and Markets, the demand for high-speed strapping machines is increasing, with an expected growth rate of 5.4% annually through 2025. Ensuring that the machine can handle the required output without bottlenecking is essential for maintaining workflow efficiency.

Another vital factor is the type of strapping material used. Automatic strapping machines can use various materials including polypropylene, polyester, and steel. The choice of material significantly affects the strength and durability of the strap, ultimately impacting the security of the packages. A review in the Journal of Packaging Technology and Research identifies that utilizing the right strapping materials can reduce product damage in transit by up to 30%. Therefore, it’s imperative to evaluate the specific requirements of the products being strapped and choose a machine that can accommodate the preferred material types.

Lastly, ease of maintenance and operation should not be overlooked. A user-friendly interface and routine maintenance protocols can greatly reduce downtime and training costs. A report from the Packaging Machinery Manufacturers Institute points out that companies prioritizing easy operation generally see a 20% decrease in operational errors. As such, selecting an automatic strapping machine that integrates advanced technology with straightforward usability can prove advantageous for long-term productivity and efficiency.

The design of automatic strapping machines is set to undergo significant innovations by 2025, focusing on enhanced efficiency and user experience. One of the key developments is the integration of advanced automation and artificial intelligence. This will allow for smarter systems that can adapt to varying packaging needs. These machines will not only streamline operations but also ensure consistent quality and accuracy in strapping applications. As manufacturers continue to seek ways to optimize their packaging processes, the evolution of these systems reflects the growing demand for speed and precision.

Tips: When considering an investment in an automatic strapping machine, it’s beneficial to assess the specific needs of your production line. Look for machines that offer flexibility in strap sizes and materials, as these features can greatly enhance adaptability to different products and packaging types.

Another area of focus in future strapping machine design is sustainability. With increasing awareness around environmental impact, manufacturers are likely to adopt eco-friendly materials and energy-efficient technologies. This shift will not only address environmental concerns but can also lead to cost savings over time. Choosing machines that utilize recyclable strapping materials could become a standard practice, aligning operational goals with corporate social responsibility.

Tips: Research the environmental credentials of a machine before purchasing. Opt for models that prioritize sustainability without compromising performance, ensuring your business stays ahead in both quality and eco-friendliness.