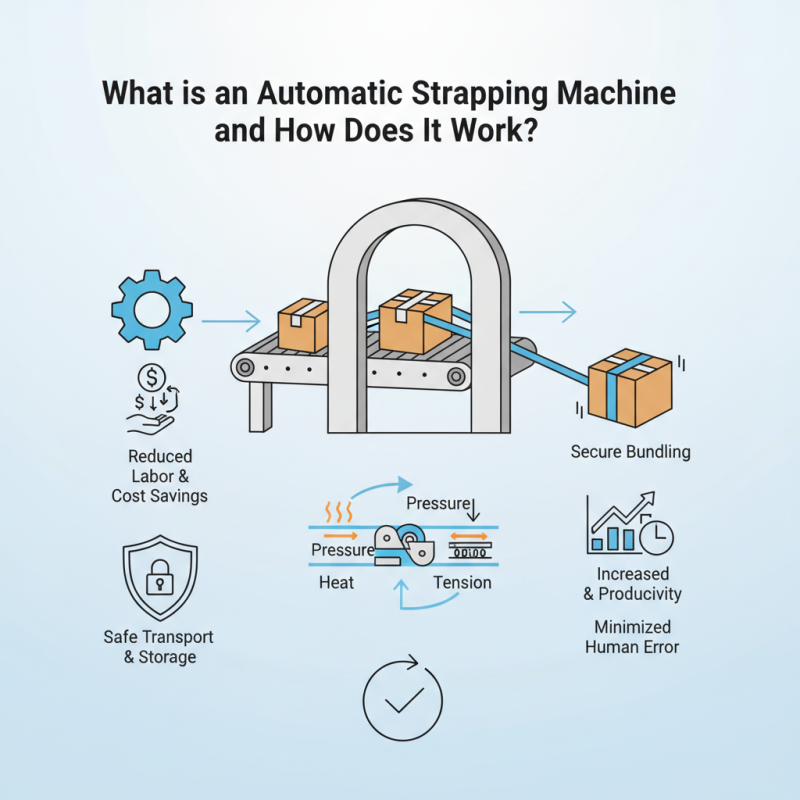

An automatic strapping machine is an essential piece of equipment in various industries, significantly enhancing the efficiency and effectiveness of packaging processes. As businesses continue to prioritize streamlined operations and cost reduction, the demand for automation in packaging has soared. The automatic strapping machine offers a reliable solution for securely bundling products, ensuring safe transport and storage while minimizing labor costs and reducing human error.

This technology operates by utilizing a combination of heat, pressure, and tension to apply a strap around packages, creating a tight seal that prevents damage during handling and shipment. Understanding how an automatic strapping machine works not only provides insights into its mechanics but also highlights the various benefits it brings to modern packaging operations. By automating this crucial step, companies can focus on optimizing their productivity and meeting the growing demands of their customers without compromising on quality or safety.

An automatic strapping machine is a mechanical device designed to apply a strap to packages or products for secure bundling and transportation. These machines are commonly used in various industries, including packaging, logistics, and manufacturing, where efficiency and reliability are crucial. By automating the strapping process, businesses can improve productivity, reduce labor costs, and enhance the overall quality of their packaging.

The operation of an automatic strapping machine typically involves several key components, including a feeding mechanism, a tensioning system, and a sealing unit. First, the product is positioned on the machine, and the strap is fed around it. The machine automatically tensions the strap to ensure a firm hold without compromising the integrity of the product. Finally, the strapping is sealed, often with heat or friction, creating a secure bond that keeps the package intact during handling and transportation. This process not only speeds up packing operations but also minimizes the risk of human error, resulting in a more consistent and reliable packaging solution.

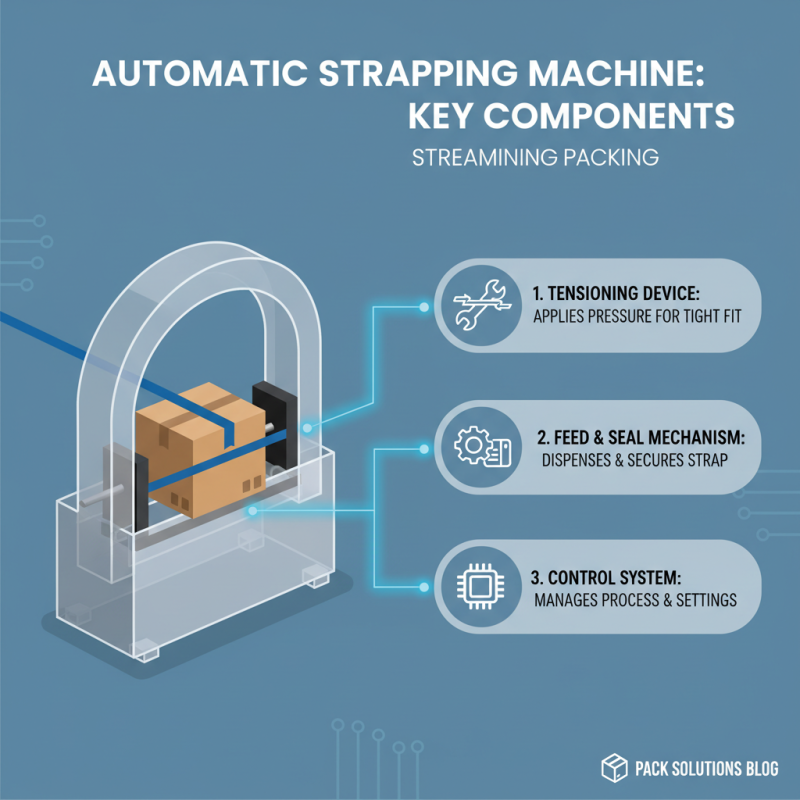

An automatic strapping machine is designed to streamline the packing process, making it essential in various industries. The key components of such a machine play a crucial role in its efficient operation. First and foremost, the tensioning device is integral as it applies the necessary pressure to ensure the strap fits tightly around the package. This component is responsible for preventing any loosening during transport, thereby ensuring the integrity of the packaged goods.

Another essential part of an automatic strapping machine is the sealing mechanism, which can vary between heat seal, friction weld, or ultrasonic technology. This mechanism securely fastens the ends of the strapping, providing a robust hold. Additionally, the feed system automates the process of placing the strap around the product, reducing manual labor and increasing speed. Lastly, the control panel allows operators to adjust settings for tension and sealing time, ensuring compatibility with different package sizes and types. Together, these components work cohesively to enhance productivity and efficiency in packaging operations.

Automatic strapping machines are essential tools in various industries, particularly in packaging and logistics. These machines operate by securing products or packages with a strap, typically made of plastic or steel, which enhances stability during transport and storage. The operation of an automatic strapping machine begins with the feeding of the product into the machine's strapping chamber where the strap is dispensed. Advanced sensors detect the presence and size of the package, ensuring a snug fit before the strap is applied. According to a market report from Grand View Research, the automatic strapping machine market is expected to grow at a CAGR of 4.9% from 2021 to 2028, indicating the increasing reliance on automated packaging solutions.

In terms of functionality, these machines utilize heat or friction to seal the strap, creating a secure bond that can withstand significant pressure. Modern automatic strapping machines are equipped with user-friendly interfaces and can be integrated with other packaging systems for a streamlined workflow. Data from Research and Markets highlights that the adoption of automation in packaging is driven by the need for efficiency and reduced labor costs, demonstrating that companies are continually seeking ways to enhance productivity.

Tips: When selecting an automatic strapping machine, consider the type of products you'll be strapping and the volume of your operations. Additionally, regular maintenance is crucial for optimal performance; it can help prevent breakdowns and extend the machine's lifespan. Investing in training for operators can also lead to improved efficiency and safety in the workplace.

Automatic strapping machines have gained popularity in various industries due to their numerous advantages. One of the primary benefits is increased efficiency. These machines are designed to strap products quickly and reliably, drastically reducing the time spent on manual strapping. This efficiency not only accelerates the packaging process but also allows companies to meet higher production demands without sacrificing quality.

Another significant advantage of using automatic strapping machines is consistency in packaging. Unlike manual methods, which can vary in application depending on the operator, automatic machines ensure uniform tension and secure strapping for each package. This consistency enhances the overall presentation of packages, reduces the risk of damage during transit, and ensures that products arrive at their destination intact. Additionally, by automating the strapping process, businesses can minimize labor costs and reduce the likelihood of human error, ultimately leading to greater operational reliability and productivity.

Automatic strapping machines play a crucial role in various industries by enhancing packaging efficiency and ensuring the integrity of products during transportation. These machines are widely used in sectors such as food and beverage, pharmaceuticals, and logistics, where they automate the process of bundling products for secure shipping. According to a report by MarketsandMarkets, the automatic strapping machine market is expected to grow from USD 1.3 billion in 2021 to USD 1.8 billion by 2026, reflecting an increasing demand for cost-effective packaging solutions.

In the food and beverage industry, automatic strapping machines help in securely bundling cartons, trays, and pallets, improving handling during distribution. The ability to strap products tightly not only prevents damages during transit but also optimizes storage space, a critical factor in supply chain efficiency. Research indicates that implementing automatic strapping technology can reduce packaging time by up to 30%, which is particularly beneficial in high-volume production environments.

Similarly, in the pharmaceutical sector, the need for compliance with stringent regulations makes high-quality packaging essential. Automatic strapping machines ensure products are securely packaged, reducing the risk of contamination and ensuring traceability. The global pharmaceutical packaging market was estimated to reach USD 120 billion in 2021, and the use of automated processes like strapping plays a significant role in meeting both efficiency and regulatory requirements. With advancements in technology, these machines continue to adapt to the evolving needs of various industries, enabling safer and more efficient packaging solutions.