In the fast-paced world of logistics and warehousing, efficiency and cost-effectiveness are paramount for ensuring smooth operations. One essential tool for achieving these goals is the pallet strapper, a device specifically designed to secure items on pallets for shipping and storage. The right pallet strapper can significantly enhance productivity by streamlining the packaging process, reducing labor costs, and minimizing the risk of product damage during transit.

Understanding the diverse range of pallet strappers available on the market is crucial for businesses looking to optimize their packaging operations. Factors such as strap tensioning, speed, and ease of use should be carefully assessed to choose the best option that meets specific operational needs. Additionally, investing in a high-quality pallet strapper can lead to substantial cost savings over time, making it an essential consideration for companies aiming to improve their bottom line.

This exploration into the world of pallet strappers will delve into the features that contribute to efficient packaging and how selecting the right model can transform both productivity and cost-effectiveness in any warehouse or distribution center.

Pallet strappers play a critical role in the packaging industry, providing an essential function in securing products during shipping and storage. According to a report from the Material Handling Institute, companies can achieve up to a 20% reduction in shipping costs by utilizing effective strapping solutions that enhance load stability. This is particularly important as logistical efficiency directly impacts the bottom line for businesses. By ensuring that products remain tightly bundled, pallet strappers mitigate the risk of damage during transit, which can lead to significant financial losses.

Furthermore, a study by the Packaging Machinery Manufacturers Institute indicates that automated strapping machines can increase packaging throughput by up to 50%. This efficiency not only speeds up the packaging process but also allows for more streamlined operations within warehouses and distribution centers. As industries continue to seek cost-effective solutions, the implementation of high-quality strapping systems becomes a strategic advantage, enabling companies to meet consumer demands while maintaining control over their operational costs. With the ongoing evolution of packaging technology, the focus on efficient pallet strapping solutions is more important than ever for businesses looking to thrive in a competitive market.

This chart illustrates the cost efficiency of different pallet strapping methods based on material costs and time taken for packaging.

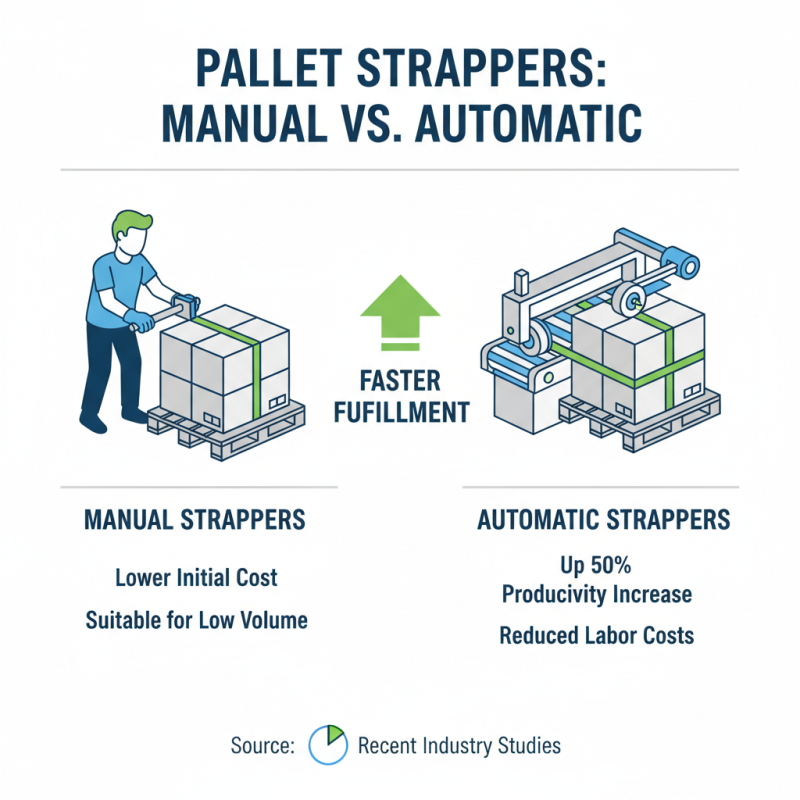

In the realm of efficient packaging, selecting the right pallet strapper is crucial in streamlining operations and achieving cost savings. The two primary options available in the market are manual and automatic pallet strappers, each catering to different business needs and operational scales. According to recent industry studies, automated strapping systems can increase productivity by up to 50% compared to manual methods, significantly reducing labor costs and time spent on packaging tasks. This efficiency often translates into faster order fulfillment and enhanced supply chain performance.

Manual pallet strappers, on the other hand, are more cost-effective for smaller operations or lower-volume packaging. While they may require more physical effort and time, they provide flexibility and ease of use in diverse work environments. The decision between manual and automatic systems should be based on the specific volume of goods handled, budget constraints, and desired efficiency levels. Reports indicate that businesses scaling from manual to automated strap systems often see a return on investment within the first year due to decreased labor and material wastage.

**Tips**: When considering a pallet strapper, analyze your volume of goods and the complexity of your packaging process. For operations managing high throughput, investing in automatic strapping systems may offer long-term savings. Conversely, for those with sporadic strapping needs, manual options can remain a viable and economical choice. Always ensure the chosen system aligns with your overall operational strategy to maximize efficiency and reduce costs.

When selecting a pallet strapper for efficient packaging and cost savings, it's essential to consider several key features that can enhance operational efficiency. First and foremost, look for a machine that offers adjustable tension settings. According to industry reports, using optimal tension can reduce material costs by up to 20%, as products remain securely bundled during transportation without risking damage. Adjustable settings allow flexibility to accommodate various load sizes, which is critical in diverse packaging environments.

Another vital feature is the machine's speed and performance. A high-speed pallet strapper can wrap pallets in as little as three seconds, significantly improving workflow efficiency. Data shows that businesses that invest in faster equipment experience up to 30% increased productivity while reducing labor costs. Additionally, user-friendly controls and automated functionalities can contribute to a smoother operation, decreasing the likelihood of operator error and wasted materials.

Lastly, consider the durability and maintenance requirements of the strapper. Durable models that are designed for high-volume use often translate to lower long-term costs. Research indicates that companies that prioritize robust machinery see a 15% reduction in total maintenance expenses, owing to fewer breakdowns and longer lifespans of their equipment. Investing in a pallet strapper with these key features not only enhances efficiency but also drives significant cost savings.

When considering the investment in pallet strappers, businesses must focus on the long-term savings these machines can provide. According to a report by the Packaging Machinery Manufacturers Institute (PMMI), automated pallet strapping systems can reduce labor costs by up to 30%, as they minimize the need for manual packaging processes. These strapping machines not only enhance packaging efficiency but also ensure consistent and reliable securing of goods, which decreases the likelihood of product damage during transit.

Moreover, a comprehensive cost analysis conducted by Supply Chain Management Review indicates that companies using pallet strappers experience a reduction in material waste by approximately 20%. This is largely due to the repeatable nature of automated strapping, which allows for optimal use of strapping materials. By decreasing waste and improving speed, businesses can achieve a payback period on the investment of a pallet strapper in less than 12 months on average. These findings underline the point that while the initial purchase of a pallet strapper is a significant expense, the resulting cost savings and operational improvements make it a wise long-term investment.

When it comes to efficient packaging and cost savings in the logistics industry, choosing the right pallet strapper is crucial. The market offers a range of models that cater to various needs and budgets. Whether you're operating a small warehouse or a large distribution center, selecting a reliable pallet strapper can significantly streamline your packaging process, improve productivity, and reduce material costs.

One of the top contenders in the market is the semi-automatic strapper, which combines ease of use with efficiency. These machines can handle a variety of package sizes and types, making them versatile for different applications. Additionally, fully automatic strappers are ideal for high-volume operations, minimizing labor costs while maximizing throughput. Regardless of the model, it’s essential to consider factors such as strap tension, speed of operation, and maintenance requirements when making your selection.

Tips: When evaluating pallet strappers, prioritize features that enhance usability. Look for models with user-friendly controls and quick-change capabilities for strap rolls, as this can save valuable time during operation. Additionally, consider the durability and warranty of the equipment to ensure long-term reliability and minimize downtime associated with repairs. Always conduct a thorough cost-benefit analysis to ensure you are making an investment that will pay off in efficiency and savings.