In the logistics and shipping industry, stretch wrap has become essential for ensuring the safety and security of goods. According to a report from Smithers Pira, the global stretch film market was valued at approximately $8 billion in 2020 and is expected to grow significantly. This growth underscores its importance as businesses seek to optimize their packaging solutions. Stretch wraps are designed to tightly secure products, preventing damage during transit and storage.

However, not all stretch wrap options are equal. The effectiveness of a stretch wrap depends on its thickness, material, and transparency. For example, lighter gauge wraps are more efficient for lighter loads, while heavier wraps are ideal for heavier items. Some users still underestimate the importance of choosing the right type. This can lead to product damage and financial loss, reflecting a need for better awareness and education within the industry.

As more companies recognize the benefits of high-quality stretch wraps, they must evaluate their options carefully. Understanding how to choose the best stretch wrap can lead to significant cost savings and improved efficiency. With the right wrap, businesses can enhance their operational processes, ensuring products arrive at their destination intact and secure.

When choosing stretch wrap for shipping and storage, material type is crucial. Most wraps come in two primary materials: polyethylene and polyolefin. Polyethylene is the most common. It offers good puncture resistance and is often used for palletizing goods. It also clings well, ensuring items stay secure during transport.

Polyolefin, on the other hand, is more versatile and resistant to temperature changes. It can stretch more than polyethylene without breaking. This makes it ideal for wrapping irregularly shaped items or fragile goods. However, it can be pricier, which may not suit everyone's budget.

Tips: Always consider the weight of the items being wrapped. Heavier loads may require a thicker gauge wrap. Additionally, test the stretchability of the material beforehand. Not all wraps have the same cling, and some may lose grip over time. For long-term storage, using a UV-resistant stretch wrap can prevent damage from sunlight. This is especially important for items sensitive to light. Remember, the right wrap can mean the difference between safe delivery and damage.

When selecting the right stretch wrap, several key features come into play. The thickness of the film is crucial. A typical range is 60 to 120 gauge. Thinner wraps may not provide enough support, while thicker options can be costlier and harder to handle. According to a recent report by the Packaging Industry Association, films within this thickness range can reduce damage during transport by up to 30%.

Another important aspect is the elasticity of the wrap. A stretch wrap's ability to stretch effectively can enhance load stability. Optimal elasticity allows the film to conform tightly to items, preventing movement. Some studies indicate that more elastic films can reduce shipping damages more effectively, improving the total cost of shipping.

Additionally, the type of stretch wrap should match the application. For instance, hand or machine application varies greatly. An industry trend shows that machine wraps often have higher tensile strength. Yet, they can be less flexible for smaller packages. Ultimately, ensuring the proper balance between these features is essential, or you might risk ending up with products that do not meet your needs and expectations.

When looking for stretch wrap options, consider the unique offerings of different brands. Some wraps excel in clinginess, ensuring items stay securely wrapped during transit. Others provide UV protection, which is essential for outdoor storage. Each brand has distinct features that may fit your specific needs.

Tips: Choose a stretch wrap with a thickness that matches your items' weight. Thicker wraps are useful for heavy equipment, while lighter ones suffice for smaller packages. Test the cling quality before buying a large quantity. It's crucial to avoid low-quality wraps that can tear easily.

Another aspect to think about is the width of the roll. Wider rolls cover more surface area, reducing wrapping time. If you're handling bulky items, a wider roll can enhance efficiency. However, narrow rolls may be easier to handle for smaller parcels. Reflect on your related costs when selecting the width. It can sometimes be a compromise between ease and expense.

Remember, not all stretch wraps are created equal. Some may stick too tightly, making it hard to unwrap later. Others might not adhere well, leading to loose packaging. Always try different options to find what truly works for you.

| Features | Measurement | Material Type | Thickness | Stretch Percentage | Suitable For |

|---|---|---|---|---|---|

| High clarity, UV protection | 18" x 1500' | Polyethylene | 80 gauge | Up to 300% | Pallets, boxes |

| Self-adhering, no residue | 20" x 1000' | LDPE | 60 gauge | Up to 250% | Retail, storage |

| Heavy-duty, tear resistant | 15" x 500' | Polyethylene | 90 gauge | Up to 350% | Industrial shipping |

| Biodegradable, eco-friendly | 12" x 1000' | PLA | 50 gauge | Up to 200% | Food service, light items |

| High stretch, cling | 10" x 1500' | Polyethylene | 70 gauge | Up to 280% | Home use, crafts |

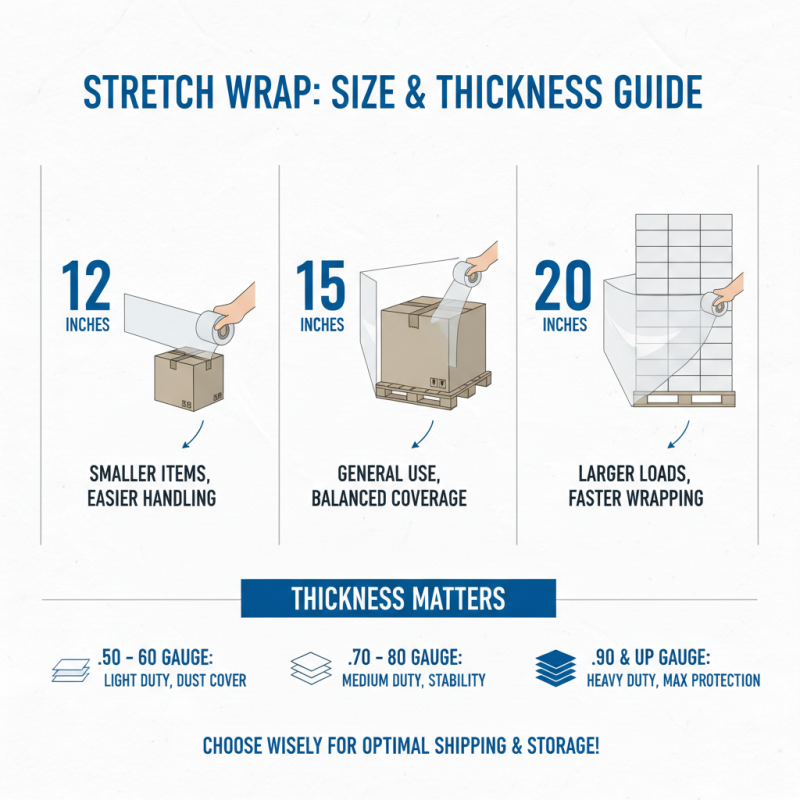

When considering stretch wrap for shipping and storage, size and thickness are essential factors. Stretch wrap typically comes in various sizes. Common widths include 12, 15, and 20 inches. Choosing the right width depends on your packaging needs. Wider wraps provide more coverage and may speed up the packing process. However, they can be harder to handle, especially for smaller items.

Thickness also plays a crucial role in the effectiveness of stretch wrap. Most options range from 50 to 90 gauge. Thicker wraps offer better puncture resistance and stability for heavy loads. But heavier options can be challenging to stretch. A balance needs to be struck between strength and ease of use. Ineffective handling may lead to wasted time or even damaged products.

Many users often overlook features like clarity. A transparent wrap allows for easy identification of items. Yet, it can be harder to find the right balance between visibility and protection. Adjusting to different environments also presents challenges. Cold temperatures can affect stretchability. Therefore, testing different wraps is essential for finding the ideal product for your specific situation.

When using stretch wrap, proper technique is crucial for effective wrapping. Start by ensuring a clean and flat surface for your items. This prevents dirt and wrinkles that could compromise safety. Overlap the wrap at least 50% to create a secure hold. Loose wrapping leads to unstable packages, increasing the risk of damage.

Pay attention to the tension you apply while wrapping. Too tight can cause tearing or deformation of the items. Conversely, too loose leaves them exposed. If you find yourself struggling with tension, take a moment to reassess. Revisiting your process can often reveal simple adjustments. Don’t rush the wrapping; it’s a critical step in your shipping routine.

After wrapping, inspect your bundles. Look for any weak points or areas that might require additional protection. Using additional layers on corners or edges often helps. Additionally, label your packages clearly, as visibility aids in organization and retrieval. Being mindful of these practices can greatly enhance your shipping and storage efficiency.