Selecting the right pallet wrapping machine is a critical decision for businesses of all sizes, as it directly impacts efficiency, productivity, and ultimately, the bottom line. With various options available in the market, understanding the specific needs of your operation is essential in making an informed choice. A pallet wrapping machine not only streamlines the packaging process but also ensures the secure transport of goods, protecting them from damage and facilitating easier handling.

When determining which pallet wrapping machine best suits your business requirements, several factors come into play. These include the types of products being wrapped, the volume of output needed, and the available space for machinery. Additionally, considering the machine's features—such as automatic versus manual operation, wrapping speed, and film type compatibility—can significantly influence your productivity.

By carefully assessing these elements, businesses can select a pallet wrapping machine that enhances their logistics efficiency and meets their unique operational demands. This guide will explore key considerations and tips to help you navigate the selection process, ensuring a tailored solution that aligns with your business goals.

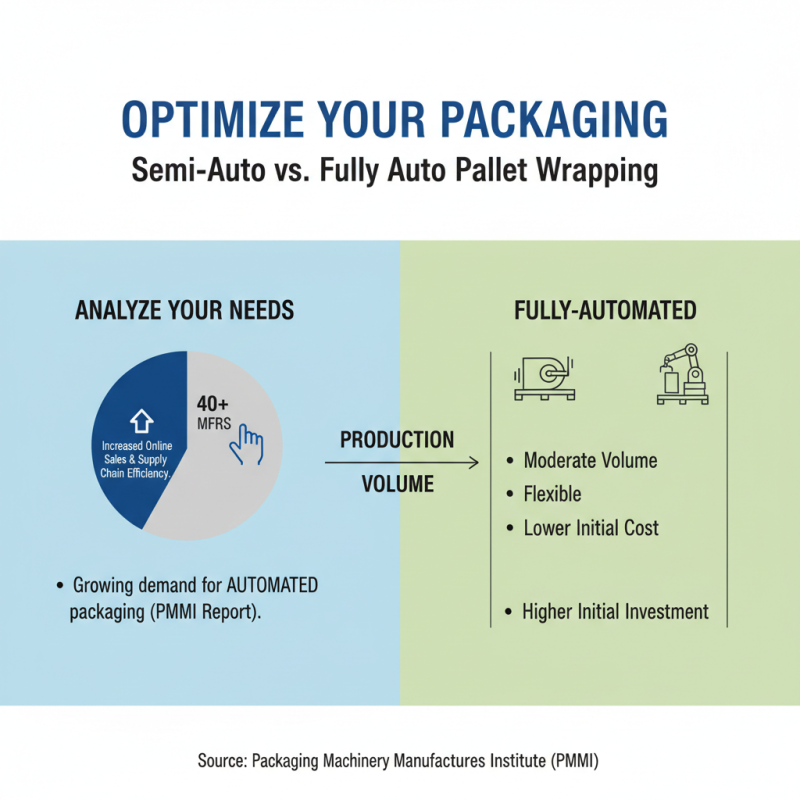

When selecting a pallet wrapping machine, it is crucial to understand the various types available and how they align with your business needs. The two primary categories are semi-automatic and fully automatic machines. Semi-automatic machines require some manual intervention, making them ideal for businesses with lower volume needs or those just beginning to implement automated solutions. According to industry reports, semi-automatic machines can increase productivity by up to 80% while being cost-effective for small to medium-sized operations.

In contrast, fully automatic pallet wrapping machines are designed for high-volume production environments. These machines can operate with minimal human oversight, allowing for rapid wrapping at rates exceeding 100 loads per hour. Industry data indicates that fully automatic systems can lead to a significant reduction in labor costs and wrapping material waste, enhancing overall operational efficiency. Furthermore, advanced features like stretch film pre-stretching can maximize load stability and improve supply chain processes, making them a worthy investment for larger operations. Understanding the specific demands of your production environment will help you determine which type of machine will offer the best return on investment and efficiency gains.

When evaluating your business volume and packaging needs, the first step is to analyze the scale of your operations. According to a report by the Packaging Machinery Manufacturers Institute (PMMI), over 40% of manufacturers in the North American market are experiencing a surge in demand for automated packaging processes due to increased online sales and the need for efficient supply chain management. Understanding your production volume will help you determine whether a semi-automated or fully automated pallet wrapping machine is more suitable for your business.

In addition to volume, it’s crucial to consider the types of products being packaged. The dimensions and weight of your items will directly affect the choice of wrapping machine; lighter, irregularly shaped loads may require a different approach compared to heavier, uniform pallets. A study from Allied Market Research indicates that the global pallet wrapping machine market is projected to reach $5.5 billion by 2025, highlighting the growing importance of tailored packaging solutions in meeting diverse operational demands. Therefore, assessing the characteristics of your products alongside the anticipated order volume will ensure that you choose a machine that enhances efficiency and supports scalability in your packaging line.

When selecting the right pallet wrapping machine, one of the critical considerations is the available space within your operation. Space constraints can significantly impact the efficiency of your packaging process, and it's essential to assess your facility's layout before making a decision. Measure the area where the machine will be installed, ensuring ample room for maneuvering pallets in and out without obstruction. This consideration prevents bottlenecks and allows for smoother workflow.

Additionally, machine dimensions should match your operational needs. Larger machines may provide increased capacity for high-volume operations, but they also require more floor space, which could be limited. A compact, well-designed machine might fit better in tight spaces while still delivering effective wrapping. Take into account the height and width of the pallets you handle, as this will influence the choice of machine size and type.

**Tips:**

- Create a detailed floor plan of your workspace to visualize how different machines fit into your current setup.

- Evaluate the height clearance above your wrapping area; some machines have overhead components that need sufficient space.

- Consider future growth; choosing a machine that slightly exceeds your current needs can provide flexibility as your business expands, without requiring another costly investment soon.

| Machine Type | Dimensions (LxWxH in cm) | Weight Capacity (kg) | Required Space (LxW in m) | Wrap Speed (pallets/hour) | Power Requirement (kW) |

|---|---|---|---|---|---|

| Semi-Automatic Wrapper | 150 x 80 x 200 | 1200 | 3 x 2 | 20 | 1.5 |

| Fully Automatic Wrapper | 180 x 100 x 230 | 1500 | 4 x 3 | 30 | 2.0 |

| Rotary Arm Wrapper | 160 x 90 x 210 | 1300 | 3.5 x 2.5 | 25 | 1.8 |

| Straddle Wrapper | 140 x 75 x 190 | 1100 | 3 x 2 | 15 | 1.2 |

When selecting a pallet wrapping machine, it's essential to explore the key features and technology options that best align with your business operations. One of the primary considerations is the type of wrapping technology used, such as stretch or shrink wrapping. Stretch wrapping machines often provide greater efficiency and cost-effectiveness for high-volume operations, while shrink wrapping may be more suitable for products that require additional protection and tamper resistance. Assessing the speed and capacity of the machine is crucial; select a model that can accommodate the volume of pallets your business handles without causing delays in production.

Automated features can significantly enhance the efficiency and consistency of the pallet wrapping process. Look for machines equipped with advanced controls, such as programmable settings for different products or load sizes, ensuring versatility in wrapping operations. Additionally, features like adjustable film tension and automatic film cutting can reduce waste and improve wrap quality. It's also advisable to consider machines that offer easy maintenance and operator training, as these factors can influence the long-term productivity and reliability of your wrapping solution. Understanding these technological options will equip you to make an informed decision that meets your specific business needs.

When considering the purchase of a pallet wrapping machine, it is crucial to budget not only for the initial purchase cost but also for ongoing maintenance expenses. The upfront cost can vary significantly based on the machine's capacity, features, and technology. Businesses should assess their volume of goods and frequency of use to determine the appropriate level of investment. Alternatives such as manual wrapping may initially seem cheaper but could ultimately lead to higher labor costs and inefficiencies over time.

In addition to the initial purchase, maintenance costs are an essential part of the budgeting process. Regular maintenance can prevent costly breakdowns and extend the lifespan of the machine, making it a wise investment. Companies should factor in expenses related to routine servicing, replacement parts, and potential downtime. Furthermore, training staff to operate and maintain the machine efficiently can incur costs, but it is essential for ensuring long-term performance and safety. By conducting a comprehensive financial analysis that includes both purchase and maintenance costs, businesses can make a well-informed decision that aligns with their operational needs and financial capabilities.