In today's fast-paced packaging industry, selecting the right stretch wrapper is crucial for ensuring efficiency, reducing material waste, and protecting products during transportation. According to a report by the Packaging Machinery Manufacturers Institute, the demand for stretch wrapping machinery is projected to grow by 5% annually, as more companies seek reliable solutions to enhance their packaging processes. With a variety of options available, it becomes essential for businesses to assess their specific packaging needs thoroughly.

As industry expert John Smith, a leading analyst at Lantech, emphasizes, "Choosing the right stretch wrapper can drastically reduce packaging costs while improving product safety and integrity." The optimal stretch wrapping solution must align with factors such as product type, load stability, and operational speed to achieve the desired outcomes. Whether it's a semi-automated or fully automated system, understanding the intricacies of each option will enable companies to make informed decisions that drive efficiency and profitability. In this guide, we will explore the key considerations that businesses should keep in mind when selecting a stretch wrapper, ensuring they choose the perfect solution for their unique packaging challenges.

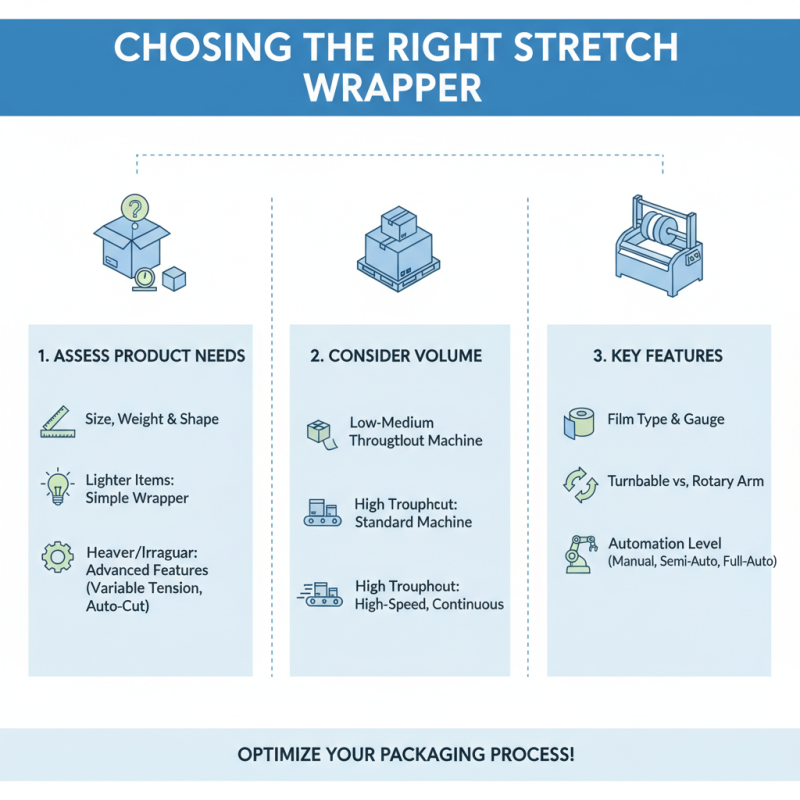

When choosing the right stretch wrapper for your packaging needs, it's essential to first understand your specific packaging requirements. Assess the types of products you will be wrapping, including their size, weight, and shape. For lighter products, a simpler stretch wrapper may suffice, while heavier or irregularly shaped items may require more advanced features, such as variable tension settings or automatic film cutting. Additionally, consider the volume of products needing wrapping; a high throughput may necessitate a more robust, high-speed machine designed for continuous operation.

Furthermore, evaluate the environment in which the stretch wrapper will be used. Factors such as humidity, temperature fluctuations, and workspace dimensions can all impact the choice of equipment. For instance, if your facility experiences high humidity, you might need a stretch film that offers better resistance to moisture. Additionally, ensure that the stretch wrapper you choose can fit comfortably within your available space while allowing for efficient workflow. By taking these elements into account, you can make a more informed decision, allowing your packaging process to run smoothly and effectively.

When it comes to selecting the right stretch wrapper for packaging needs, understanding the types available—manual, semi-automatic, and automatic—is crucial.

Manual stretch wrappers are ideal for smaller operations or businesses with limited budgets. They require an operator to wrap the load and are often seen as a cost-effective entry point. However, they can become labor-intensive and may lead to inconsistencies if not executed carefully.

Semi-automatic stretch wrappers offer a middle ground, combining the benefits of manual wrapping with automation. These machines typically require minimal manual intervention, making them suitable for medium-sized businesses looking to increase throughput without fully committing to high-end automation.

According to industry reports, semi-automatic stretch wrappers can improve wrapping efficiency by up to 30%, while also consistently applying the right amount of stretch film to optimize load stability.

For larger operations with high-volume packaging needs, automatic stretch wrappers are the best choice. These machines can operate at high speeds and with remarkable precision, reducing labor costs and increasing productivity.

Data suggests that companies utilizing automatic stretch wrappers can achieve wrapping speeds that exceed 100 loads per hour, which is essential for meeting tight shipping deadlines.

Tips: When choosing a stretch wrapper, assess your production volume and load size first. Consider how often you will need to change film rolls or adjust settings, as this can impact your workflow. Lastly, always ensure that the wrapper you select complements your existing packaging processes for a seamless integration.

When selecting a stretch wrapper for your packaging needs, it's essential to understand key features that significantly impact the efficiency of your operations. The

film type is one of the most critical factors. Different films offer varied levels of strength, cling, and puncture resistance. For instance,

standard stretch film might be suitable for lighter loads, while high-performance films can provide better protection for heavier or irregularly shaped items. Consider the specific requirements of your products when choosing the film type to ensure optimal load stability and protection during transportation.

Another important feature to evaluate is the wrap quality. The ability of the wrapper to produce tight and consistent wraps can make a substantial difference in the integrity of packaged goods. Assess the machine's capability to achieve consistent tension and overlap during the wrapping process. A reliable stretch wrapper should also account for variations in package size and shape, adapting accordingly to deliver a secure wrap without excessive material usage.

Tips: Make sure to conduct a thorough analysis of your packaging volume and the typical dimensions of your products. This understanding will help you decide on the turntable speed necessary for your operations. A machine with adjustable turntable speed can accommodate various products and enhance productivity. Regular maintenance of your stretch wrapper will also ensure it continues to perform at its best, thereby reducing downtime and optimizing your packaging process.

When evaluating the cost-effectiveness of stretch wrappers, it's essential to focus on two primary metrics: return on investment (ROI) and operational efficiency. ROI is calculated by comparing the financial benefits gained from the new equipment against its total costs, including purchase price, maintenance, and operating expenses. A compelling ROI indicates that the stretch wrapper will not only pay for itself over time but also contribute positively to the overall profitability of the operation. This analysis helps businesses prioritize models that offer the best long-term financial returns.

Operational efficiency metrics further enhance decision-making by assessing productivity and resource utilization. Factors such as speed, ease of use, and the reduction of material waste play crucial roles in determining how effectively a stretch wrapper can operate within existing workflows. By measuring the throughput and time saved in packaging processes, organizations can identify the models that optimize their labor efforts and minimize downtime. Understanding these metrics allows companies to make informed decisions that align with their packaging needs and improve overall process efficiency.

In recent years, sustainability has become a focal point in the packaging industry, and stretch wrapping is no exception. Eco-friendly materials and practices can significantly reduce the carbon footprint of your packaging processes. For instance, industry reports indicate that switching to biodegradable stretch films can cut down plastic waste by up to 50% compared to traditional plastic options. Moreover, using recycled materials in your stretch films not only lessens environmental impact but also aligns with global movements toward circular economies.

When considering eco-friendly stretch wrapping options, it's essential to evaluate the film's thickness and load stability. Thinner films can be just as effective when optimized properly, thereby reducing material usage. Furthermore, utilizing advanced wrapping techniques such as pre-stretching can enhance the efficiency of the wrapping process, requiring less material while providing equivalent load security.

Tips for selecting sustainable options include sourcing films that carry certifications for recyclability and utilizing machinery that minimizes energy consumption during the wrapping process. Additionally, training employees on best practices for stretch wrapping can ensure maximum efficiency and reduce waste. By adopting these eco-friendly practices, companies can not only meet their packaging needs but also contribute positively to environmental conservation.