Choosing the right pallet strapper can significantly impact your packaging operations. Properly securing loads is crucial for transportation and storage. This tool comes in various types, each designed for different applications. Understanding your specific needs is essential.

When selecting a pallet strapper, consider the materials you'll use. Lightweight versus heavy-duty strapping requires different tools. Think about the frequency of use, which will determine the durability needed. Budget constraints may affect your choice, but investing in quality can lead to long-term benefits.

Also, user-friendliness is a key factor. Some tools are easier to operate than others, especially under pressure. It's important to try various options if possible before committing. Remember, the wrong choice could lead to wasted materials and labor. When selecting the right pallet strapper, reflect on both immediate needs and future scalability.

When selecting a pallet strap tool, understanding the types available is essential. There are

manual, pneumatic, and electric options.

Manual tools are often simpler and less expensive. They require physical effort, which can be tiring over time. Still, they offer control for smaller tasks.

Pneumatic tools are quick and efficient. They work best in busy warehouses. However, they need an air compressor, which adds complexity. Some users find it challenging to manage air supply while operating. Meanwhile, electric tools offer convenience but can be heavier. The weight might affect mobility in tight spaces.

Each type has its strengths and weaknesses. Consider the nature of your tasks. Think about frequency and volume. A bustling environment may favor pneumatic tools. Yet, personal preference plays a significant role. It’s important to reflect on your workflow. Choosing the right tool can improve efficiency but may require some trial and error.

When selecting a pallet strap tool, consider its key features carefully. Durability is essential. Look for tools made from robust materials. These tools should withstand rough usage and last longer. A lightweight design is beneficial, making it easier to handle. Heavy tools can cause fatigue during prolonged use.

Tip: Test the tool before purchasing. This can reveal how it feels in your hand. Poor ergonomics can lead to discomfort.

Next, assess the tool’s compatibility with various strap sizes. Not all tools work with every strap width. A versatile tool can save time. Ensure it offers features like tensioning and cutting. These functionalities streamline your process.

Tip: Check user reviews. Genuine feedback can highlight both advantages and potential drawbacks. Some tools may break easily or not function well under pressure. Being aware of these issues can guide your choice. Remember, the wrong tool can lead to inefficient packing.

| Feature | Description | Importance |

|---|---|---|

| Type of Strapping | Considers whether plastic, steel, or polyester strapping is needed based on weight and durability requirements. | High |

| Tool Weight | The weight of the tool can affect user comfort and productivity during long periods of operation. | Medium |

| Ease of Use | Look for tools that offer user-friendly operation to minimize training time and improve efficiency. | High |

| Adjustability | Tools with adjustable settings provide flexibility for different sizes of pallets and loads. | Medium |

| Durability | Consider tools made from robust materials that can withstand heavy use. | High |

| Safety Features | Look for tools that have safety features to protect users from accidents. | High |

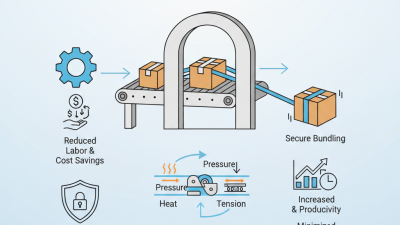

When choosing a pallet strap tool, compatibility with your strapping material is crucial. Different materials, like polypropylene and polyester, require specific tools. For example, polypropylene is lighter and easier to handle. Polyester, on the other hand, is stronger and often used for heavier loads. Understanding these differences helps in selecting the right tool for your needs.

Tips: Test your strapping material before making a purchase. This can prevent future issues. If you often change materials, consider a versatile tool capable of handling multiple types. It might be a bit challenging to find one tool that excels in every situation.

Always evaluate the friction or heat caused during strapping. Some materials react differently under pressure. Pay attention to these details. They can affect your packaging quality. If you notice fraying or splitting, reflect on the tool's suitability for your material choice.

When selecting a pallet strap tool, it’s crucial to consider the compatibility with various strapping materials. The following chart illustrates the average compatibility rating of different tools with commonly used strapping materials.

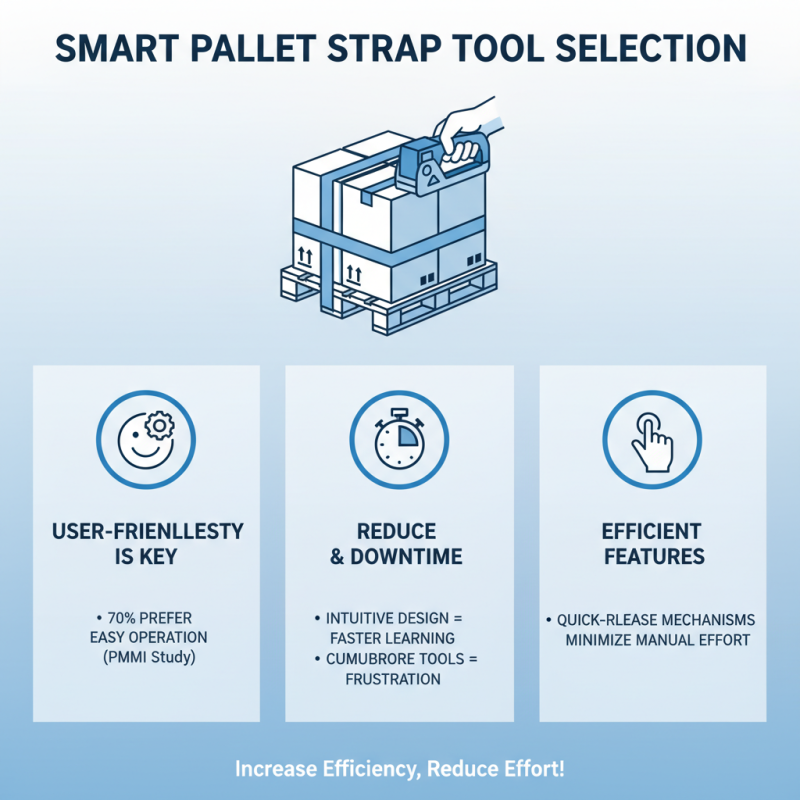

When selecting a pallet strap tool, user-friendliness is crucial. A study by the Packaging Machinery Manufacturers Institute found that 70% of users prefer tools that enhance ease of operation. An intuitive design can significantly reduce training time for employees. Tools that are cumbersome may lead to frustration and increased downtime. Efficient tools often include features like quick-release mechanisms, which allow for swift adjustments and minimize manual effort.

Efficiency is measured by how quickly a tool can complete tasks. A report from the International Journal of Packaging Technology highlighted that efficient strapping tools can reduce packaging time by up to 30%. This not only boosts productivity but also optimizes labor costs. Some tools may lack sufficient power for high-tension applications, which can result in failures. It’s essential to balance power and usability to prevent operational hitches.

While evaluating options, consider accessibility and service needs. Some tools are straightforward to maintain, while others can require specialist assistance. Many organizations overlook the total cost of ownership, including repairs and replacements. This oversight can impact overall efficiency and user satisfaction in the long run. A tool that is user-friendly yet efficient can lead to a smoother workflow and better employee morale.

When selecting a pallet strap tool, budget considerations play a crucial role. A high-quality tool can greatly enhance efficiency, but the initial investment is vital. Basic models can be affordable, yet they may not withstand daily demands. Evaluate how often you will use the tool and the types of materials you will work with. This assessment can help you determine if spending more upfront is worth it.

Tips: Consider buying used equipment. Sometimes, you can find reliable tools at a fraction of the price. Be cautious, though. Check for wear and tear before making a purchase. Another element is maintenance costs. A cheaper tool may require more frequent repairs, leading to higher long-term expenses.

Cost-effectiveness goes beyond the purchase price. Think about the total cost of ownership. A more expensive tool might offer durability and efficiency. This combination can save both time and money over time. Evaluate your priorities and how they relate to your budget. Sometimes, investing a little more makes a big difference. Reflect on your needs. A well-chosen tool can ultimately enhance productivity and reduce frustration in your daily tasks.