The stretch wrap dispenser is a vital tool in packaging and logistics. This device simplifies the process of applying stretch film around products or pallets for shipping. According to market research, the global stretch film market is expected to exceed $14 billion by 2026. This growth is driven by the surge in e-commerce and the need for effective protective packaging.

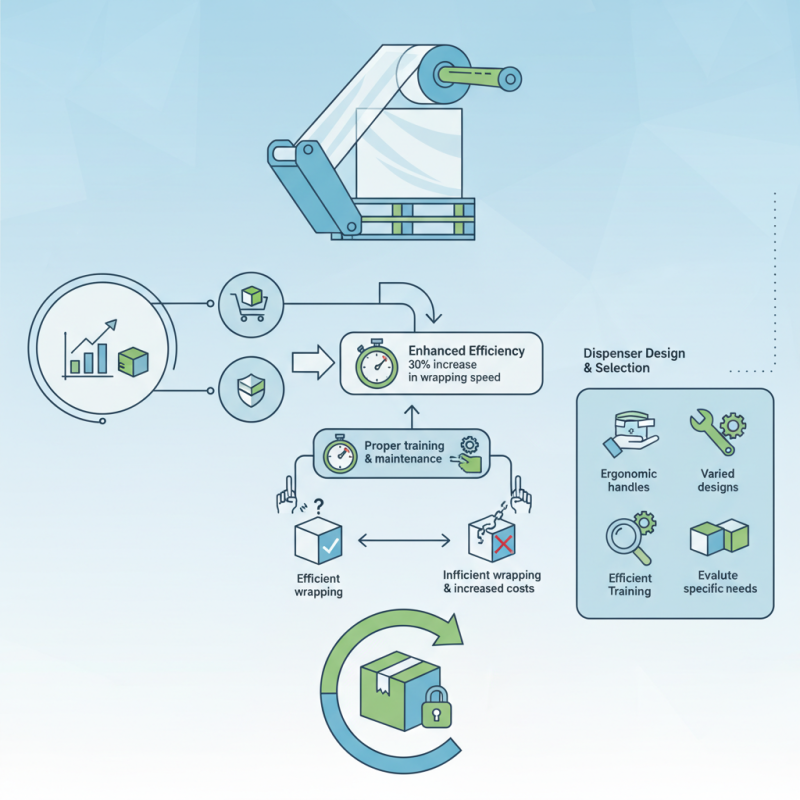

Using a stretch wrap dispenser can enhance efficiency. It minimizes the time required to wrap goods, which is crucial in fast-paced environments. A study noted that companies using dispensers reported a 30% increase in wrapping speed. However, not all businesses utilize this tool effectively. Some overlook proper training and maintenance, which can lead to inefficient wrapping and increased costs.

The design of stretch wrap dispensers varies significantly. Many models feature ergonomic handles to reduce strain. Yet, not every model suits all packaging types. It's important for businesses to evaluate their specific needs. Understanding how to choose the right dispenser can make a significant difference in overall effectiveness and product protection.

A stretch wrap dispenser is an essential tool in packaging and shipping. It helps efficiently apply stretch film around items for protection. This method is critical in securing goods on pallets. It not only saves time but also improves safety. According to industry data, nearly 80% of shipments use stretch wrap for stability and protection.

Using a stretch wrap dispenser enhances the wrapping process. Workers can easily control the tension and coverage of the film. Efficient application prevents waste and reduces labor costs. Reports indicate that businesses can save up to 30% in material costs when using dispensers correctly. However, improper use still occurs. Many workers struggle with inconsistent tension, leading to inadequate wrapping.

Additionally, the ergonomics of a stretch wrap dispenser should not be overlooked. A poorly designed tool can cause fatigue and repetitive strain injuries. Training staff on using these dispensers is also essential for best results. Failing to do so can lead to wrapping mistakes and damage to products. Continuous assessment of wrapping techniques is vital for operational efficiency.

The chart below illustrates the usage of stretch wrap dispensers in different industries based on the percentage of total users. The data highlights the most common applications for these dispensers.

A stretch wrap dispenser is essential for efficient packaging. Understanding its components can help you use it better. The main parts include the frame, handle, and roll holder. The frame provides stability, while the handle allows for easy maneuvering. The roll holder keeps the film in place during use.

Tips for using a stretch wrap dispenser can enhance your experience. Make sure to adjust the tension correctly. Too much tension can lead to breakage. Ensure the film is aligned properly to avoid tangling. Using the device at waist height can also help reduce strain.

Pay attention to the size of the film roll. A larger roll might seem convenient but can be unwieldy. It’s worth experimenting with different sizes. Remember, practice makes perfect. You could reflect on your past experiences to improve your technique.

A stretch wrap dispenser is a handy tool for wrapping items securely. It helps in easily applying stretch film around products. Using it effectively saves time and reduces waste.

To use a stretch wrap dispenser effectively, begin by placing the roll of film on the dispenser. Make sure it’s secure. Hold the handle firmly. As you move, guide the film around the items. Overlap the layers slightly. This creates a tighter wrap. Keep a steady pace and tension. It's important not to rush. Uneven pressure can lead to loose spots.

Tips: Always check the film for defects before starting. A small tear can cause headaches later. Practice makes perfect. Don't hesitate to experiment with different wrapping techniques. Sometimes, a simple adjustment in your movement can improve the result.

Keep in mind that wrapping is an art. Every item has unique needs. Some might need tighter wraps, while others require looser ones. Be mindful of the product’s shape and vulnerability. It’s okay to revisit your wrapping methods. Refinement takes time and experience. Let your technique evolve with each use.

| Feature | Description | Benefits |

|---|---|---|

| Ergonomic Design | Designed to reduce strain on the user while wrapping pallets. | Enhances user comfort and efficiency during use. |

| Adjustable Tension | Allows the user to control the tightness of the wrap around the load. | Prevents damage to goods by enabling optimal wrapping pressure. |

| Built-in Cutter | Features a cutting mechanism for easy access and use. | Increases efficiency by eliminating the need for separate cutting tools. |

| Variety of Size Options | Available in various sizes to accommodate different roll widths. | Versatile for various shipment sizes and types of loads. |

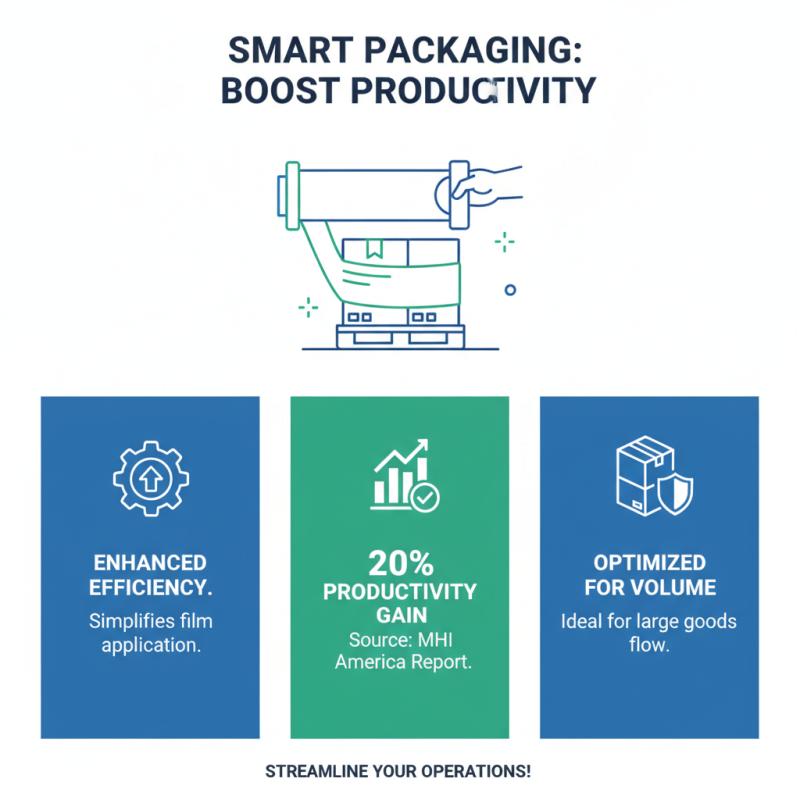

Using a stretch wrap dispenser can greatly enhance efficiency in packaging. This tool simplifies the process of applying stretch film around products. According to a report by the Material Handling Industry of America, implementing stretch wrap dispensers can increase productivity by up to 20%. This is crucial for businesses that handle large volumes of goods.

One of the primary benefits is the reduction in material waste. Studies indicate that using a dispenser can lower film usage by 30%. With precise wrapping, less film is required, which translates to cost savings. However, many still underestimate the importance of proper technique. Inexperienced users can waste film, negating potential savings. Training and practice are essential.

Another factor to consider is labor efficiency. Workers can wrap pallets faster with a dispenser than by hand. This leads to quicker loading times. However, not all dispensers are created equal. Some may be difficult to use or ergonomic. Regular evaluation of the chosen tool's effectiveness is vital. Companies should assess whether their current setup meets the crew's needs or requires an update.

Maintaining stretch wrap dispensers is crucial for their optimal performance. Regular maintenance can extend the lifespan of these tools and enhance productivity. According to industry reports, poorly maintained dispensers can lead to 25% more waste during packaging. This waste directly impacts operational costs.

One important tip is to clean the dispenser regularly. Dust and debris can interfere with the wrapping process. Use a soft cloth to wipe down surfaces frequently. Inspect the dispenser for any signs of wear and tear. If you notice any damage, address it immediately to avoid further complications.

Another aspect to consider is the tension setting. Adjust it based on the load being wrapped. Incorrect tension levels lead to under-wrapping or over-wrapping. This not only affects the integrity of the wrapped product but can also result in more manual labor to fix mistakes. Remember, a well-maintained dispenser contributes significantly to efficient, waste-reducing operations in any packaging environment.