Stretch wrap is a pivotal component in packaging and shipping industries. It provides protection during transportation, ensuring that products remain intact. According to a recent industry report by Smithers Pira, the global stretch wrap market is projected to reach $8.5 billion by 2025, highlighting its growing importance. Industry expert Dr. James White states, "Stretch wrap technology has transformed how we secure goods for transport."

The versatility of stretch wrap is noteworthy. It is used across various sectors, from food processing to pharmaceuticals. The film clings tightly to products, providing a barrier against moisture and dust. However, the sustainability of stretch wrap has raised concerns. Many companies are seeking alternatives to reduce plastic waste. Innovations in biodegradable options are being explored but are still in the early stages.

While stretch wrap effectively secures goods, it is essential to acknowledge its environmental impact. Each year, millions of tons of plastic are used for packaging. This presents a challenge for manufacturers and consumers alike. Striking a balance between effective packaging and environmental responsibility is crucial. The future of stretch wrap may depend on how well the industry can adapt to these challenges.

Stretch wrap is a versatile packaging material primarily used to secure products for storage and shipping. It consists of a thin, stretchable plastic film that tightly envelops various items. This wrapping solution comes in several widths and thicknesses, making it adaptable for diverse needs. It is often easy to apply, but one must ensure it is wrapped correctly to avoid damage.

The primary function of stretch wrap is to stabilize loads on pallets. It holds items in place, preventing shifting during transit. Additionally, it provides a protective barrier against dust and moisture. One might overlook specific details when wrapping, leading to inadequate security or wasted materials. Proper tension is critical when applying stretch wrap; too loose can result in a collapsed load. Conversely, too tight may damage delicate items. This balancing act requires careful attention and practice. Users sometimes rush, which can lead to errors in wrapping technique.

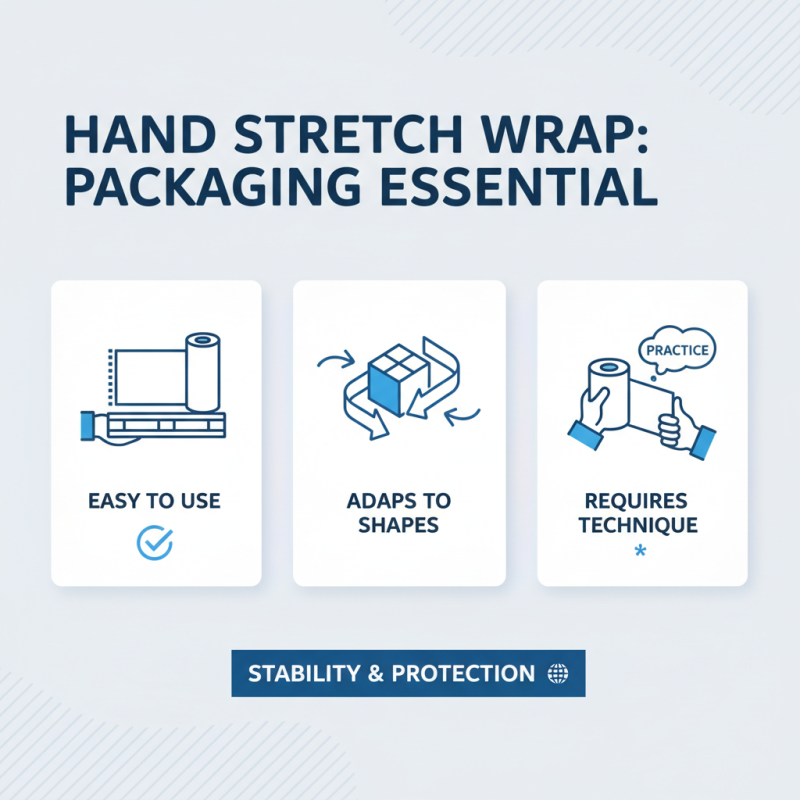

Stretch wrap is essential in packaging, providing stability and protection for various products. One common type is hand stretch wrap, which is easy to use. It allows workers to manually secure items on pallets. Hand stretch wrap is flexible and can adapt to different shapes. However, it may require practice to master proper application techniques.

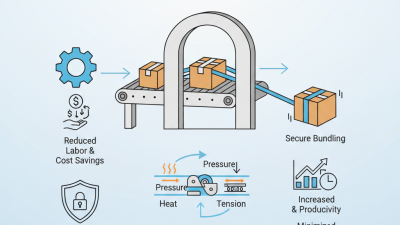

Machine stretch wrap is another type, designed for automated processes. This wrap is applied by machines, offering efficiency in high-volume settings. It can be thicker and provide better load containment. Yet, it may not be ideal for smaller operations, as the initial investment in equipment can be significant.

Colored stretch wrap adds visual appeal and aids in inventory management. It helps in identifying different products at a glance. Meanwhile, biodegradable options cater to eco-conscious businesses. These wraps break down more easily than traditional plastic, yet they may lack the same durability. Choosing the right type of stretch wrap involves weighing performance against cost and environmental impact. This decision can reflect a company's values and priorities.

Stretch wrap is an essential tool in packaging and shipping. It plays a critical role in protecting goods during transit. According to a report from Packaging World, using stretch wrap can reduce shipping damage by up to 30%. This is significant, as damaged products can severely impact a company’s bottom line. Improperly wrapped items may shift during transport, increasing the risk of damage.

The benefits of stretch wrap go beyond just protection. It provides a moisture barrier, safeguarding against environmental factors. A study by the Flexible Packaging Association found that over 66% of businesses reported fewer damages due to moisture-related issues when using stretch wrap. Additionally, it offers cost efficiency. Stretch wrap is lightweight, which helps lower shipping costs. However, not all stretch wraps are created equal. Businesses must choose the right type to maximize efficiency.

While stretch wrap is highly beneficial, some challenges exist. For instance, improper application can lead to inadequate protection. It’s crucial for staff to be trained in the correct techniques. Regular assessment of wrapping practices can improve the results. Many companies overlook this, leading to potential losses. Overall, while stretch wrap offers various benefits, careful consideration in its application is necessary.

| Feature | Description | Benefits |

|---|---|---|

| Material | Plastic film used to wrap items | Prevents damage during transportation |

| Usage | Commonly used for pallet wrapping and bundling shipments | Enhances stability of loads |

| Types | Stretch film, shrink film, and adhesive film | Versatility in application |

| Cost Efficiency | Low cost compared to other packaging methods | Reduces overall shipping costs |

| Environmental Impact | Recyclable options available | Minimized waste in packaging |

| Safety | Protects items from moisture and dirt | Increases safety during storage and transport |

Stretch wrap is versatile and widely used in many industries. It is a highly elastic plastic film. Commonly, it secures products on pallets for shipping. Warehouses appreciate its ability to stabilize loads. It minimizes movement and protects items during transportation. This film offers a lightweight alternative to traditional packaging materials.

The agricultural sector frequently uses stretch wrap for bales of hay or silage. It prevents moisture from ruining the contents. Food industries benefit too; stretch wrap keeps produce fresh. Retailers often use it to wrap pallets for easier storage. However, improper use can lead to waste. If not applied correctly, products may shift or become damaged. Industries must invest time in training for optimal application.

Stretch wrap is essential in packaging and shipping. Proper application ensures items stay secure during transit. When using stretch wrap, it is crucial to maintain the right tension. Loose wrapping can lead to shifting loads. Over-wrapping, on the other hand, wastes materials. Finding a balance is key.

One common mistake is inconsistent application. This can weaken protection and create frustration during unpacking. It's important to use even, overlapping layers. Using a dispenser can help achieve this. Additionally, keep the wrap away from sharp edges. They can cause tears or punctures. Inspecting the wrap for damage before use is vital.

Handling stretch wrap requires attention. Storing it in a cool, dry place prevents degradation. Be aware of the environment in which you work. High temperatures can make the wrap too stretchy. Cold conditions can make it brittle. Reflecting on these factors can improve overall efficiency.