In the world of packaging, efficiency is key. Case erectors play a crucial role in this process. According to Mark Johnson, a leading expert in packaging solutions, "The right case erector can dramatically boost production speed while reducing waste." Understanding the different types of case erectors available can help businesses streamline their operations.

Many manufacturers face challenges when selecting the proper case erector. Take time to consider various options. Automatic case erectors, for example, are designed for high-volume production. They can quickly form cases from flat materials. However, businesses with lower output may struggle to justify the investment. Balancing efficiency and cost is essential.

While the technology is advanced, there are also limitations. Not all case erectors handle various box sizes or materials efficiently. Companies must evaluate their specific needs. This includes understanding the strengths and weaknesses of each type. As Johnson pointed out, it’s not just about speed; it’s about finding a solution that fits your operation perfectly.

Case erectors play a crucial role in the packaging industry. They automate the process of forming cardboard boxes, significantly enhancing efficiency. By reducing manual labor, these machines help companies focus on other essential tasks. In a fast-paced market, speed is key. A reliable case erector ensures that packaging lines run smoothly.

Different types of case erecting machines cater to various needs. Some are compact, perfect for small spaces. Others handle larger box sizes, providing flexibility. However, choosing the right type can be challenging. Factors like production speed and box design require careful consideration. It's easy to underestimate the importance of compatibility. A mismatch can lead to delays in production.

While case erectors simplify packaging, they are not without flaws. Regular maintenance is necessary to avoid breakdowns. Operators must be trained properly to handle these machines. Neglecting these aspects can lead to costly mistakes. It’s essential to continuously evaluate and adapt to new technologies. Innovation is integral to staying competitive in packaging solutions.

Case erectors are essential for efficient packaging. There are three main types: manual, semi-automatic, and fully automatic. Each type serves a different purpose and suits various production needs.

Manual case erectors require operators to set them up. They are cost-effective and flexible. However, they can slow down production. Errors can occur if workers are not trained properly. This could lead to inconsistent case formation, affecting packaging quality.

Semi-automatic case erectors reduce manual effort. They require minimal operator involvement. These machines often enhance speed and accuracy. Yet, they may still struggle with higher volumes. If production increases significantly, they might become inadequate, leading to bottlenecks.

Fully automatic case erectors provide the highest efficiency. They streamline the entire packaging process. Often, they can handle large volumes continuously. However, the initial investment is higher. Maintenance and repairs can be complicated. Choosing the right type depends on assessing production needs against these variables.

When selecting a case erector, it’s important to consider several key features. Efficiency is paramount. Look for machines that can handle various box sizes. Flexibility in production helps adapt to changing demands. An easy-to-use interface can simplify operation and reduce training time for staff.

Another crucial aspect is speed. Some machines can erect and seal cases rapidly, saving valuable time in the packaging process. However, faster doesn’t always mean better. It's essential to assess the quality of the boxes produced. Flimsy cases may lead to product damage.

Durability should not be overlooked. A robust design ensures a longer lifespan and fewer maintenance issues. Pay attention to the warranty and support offered. But remember, even the best equipment can have shortcomings. Regular maintenance is necessary, as neglect can lead to costly downtimes. Check user reviews to gauge real-life performance. Judging all these factors will help you find an effective case erector.

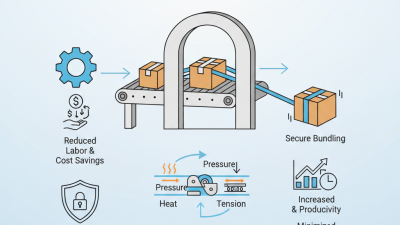

Implementing case erectors in packaging operations can lead to significant benefits. These machines automate the formation of boxes, which speeds up the packaging process. Efficiency increases as products can be packed faster and with fewer errors. Workers can focus on other tasks instead of manually assembling cases. This not only enhances productivity but also reduces labor costs over time.

Another advantage is improved consistency in packaging. Case erectors create a uniform product size, which helps maintain order and presentation. However, there are challenges too. Sometimes, machines can jam or require maintenance, leading to potential delays. Training staff to handle these issues is essential to prevent downtime. Although these machines are beneficial, they still require human oversight to ensure everything runs smoothly.

Incorporating case erectors also leads to better use of packaging materials. By ensuring each box is correctly formed, waste is minimized. Operators need to monitor material usage regularly. Adjustments may be necessary to address any overconsumption. Balancing efficiency with environmental considerations is a common struggle. These factors illustrate the need for continuous evaluation in packaging operations.

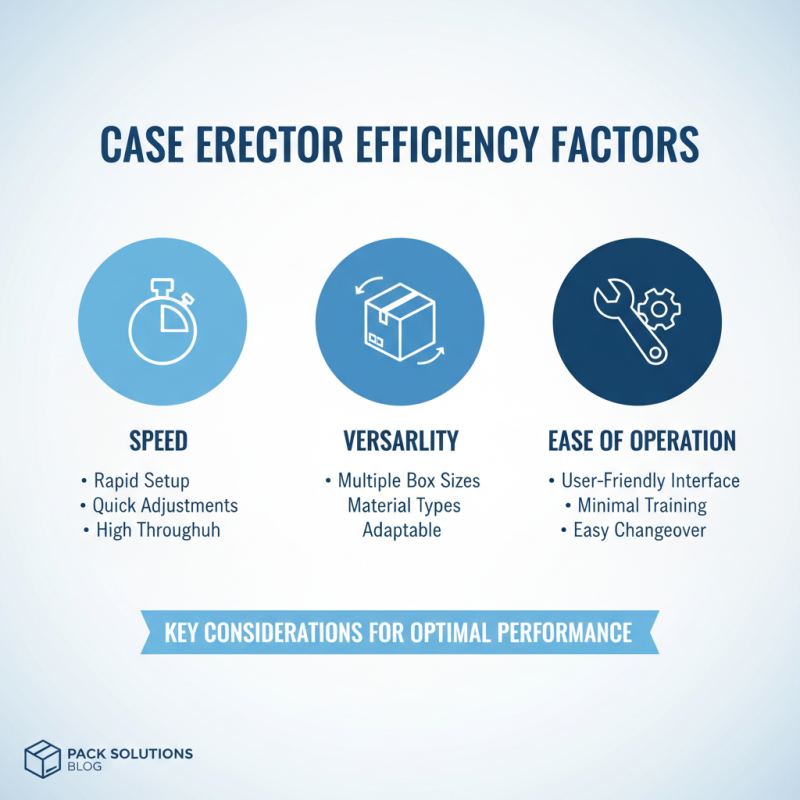

When analyzing case erectors, numerous factors influence efficiency. Speed, versatility, and ease of operation are vital. Some models excel in rapid setup, allowing for quick adjustments. Others may offer multiple box sizes but may require more time to change.

Additionally, build quality plays a crucial role. Some machines are solid and durable but can be costly. Conversely, budget-friendly options might struggle under heavy use. This trade-off often leads to reflection on priorities in the production process. Do you prioritize upfront costs or long-term reliability?

Maintenance is another aspect to consider. Easy-to-clean models help save time and reduce downtime. However, intricate designs might complicate repairs and upkeep. Striking a balance between efficiency and convenience remains a challenge as businesses expand. Finding the right case erector is not always straightforward. Specific needs can vary greatly depending on production demands.